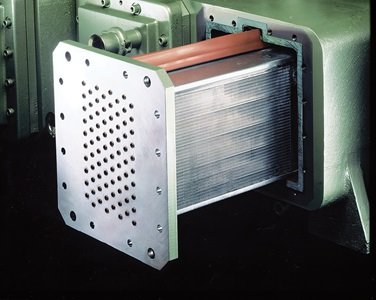

Multi-stage compression with intercooling is the most energy efficient way of reaching optimal compressor outlet pressure. Once your centrifugal compressed air system is in operation, regularly scheduled cooler preventive maintenance is critical to keep your compressor running smoothly to prevent fouling, leaks and mechanical damage. Monitoring cooling water quality and system temperature and pressure, as well as cleaning and inspecting your equipment as part of an ongoing program, will help to avoid intercooler performance degradation.

The most energy-efficient method of achieving optimal compressor outlet pressure is multi-stage compression with intercooling. Once your centrifugal compressed air system is operational, it is critical to perform regular cooler preventive maintenance to keep your compressor running smoothly and prevent fouling, leaks, and mechanical damage. Monitoring cooling water quality, system temperature and pressure, as well as cleaning and inspecting your equipment on a regular basis, will help to prevent intercooler performance degradation.