CONDENSATE DISCHARGE METHOD

Time Control Solenoid ValveFrequent failure occurs because of compression pressure directly applied to a solenoid valve. A large amount of air is lost because condensate is discharged via time setting regardless of the amount.

ANALYSIS OF A CONDENSATE ZERO AIR LOSS AUTO DRAIN VALVES

Level sensor type

- There is almost zero air loss, ensuring high economic efficiencyand fast recouping of initial investment.

- Large-size drain prevents clogging, and self-restoration for an emergency mode improves safety.

- A strainer within the product prevents collection of scale.

- Automatic operation provides easy maintenance.

- A variety of models are avaliable for smalland large capacity compressors air line.

-

- Time to open a valve is calculated based on detection by a sensor.

- An emergency mode begins after 60 sec if condensate is not properly discharged.

- The emergency mode initiates the self-restoration feature, and the valve is opened for 5 sec per every 3 min as like time control valve temporally.

- Setting Time : 5 sec per 5 min – condensate discharged for 1 sec and air lost for 4 sec.: 12 times/hr x 4sec/time = 48sec/hr

- Operation of 24 hr per day for 365 days : 24hr/day x 48sec/hr x 365day/year = 420,480sec/year

- Annual energy loss : 7.2872㎥/min x 420,480sec/year ÷ 60sec/min = 51,069㎥/year

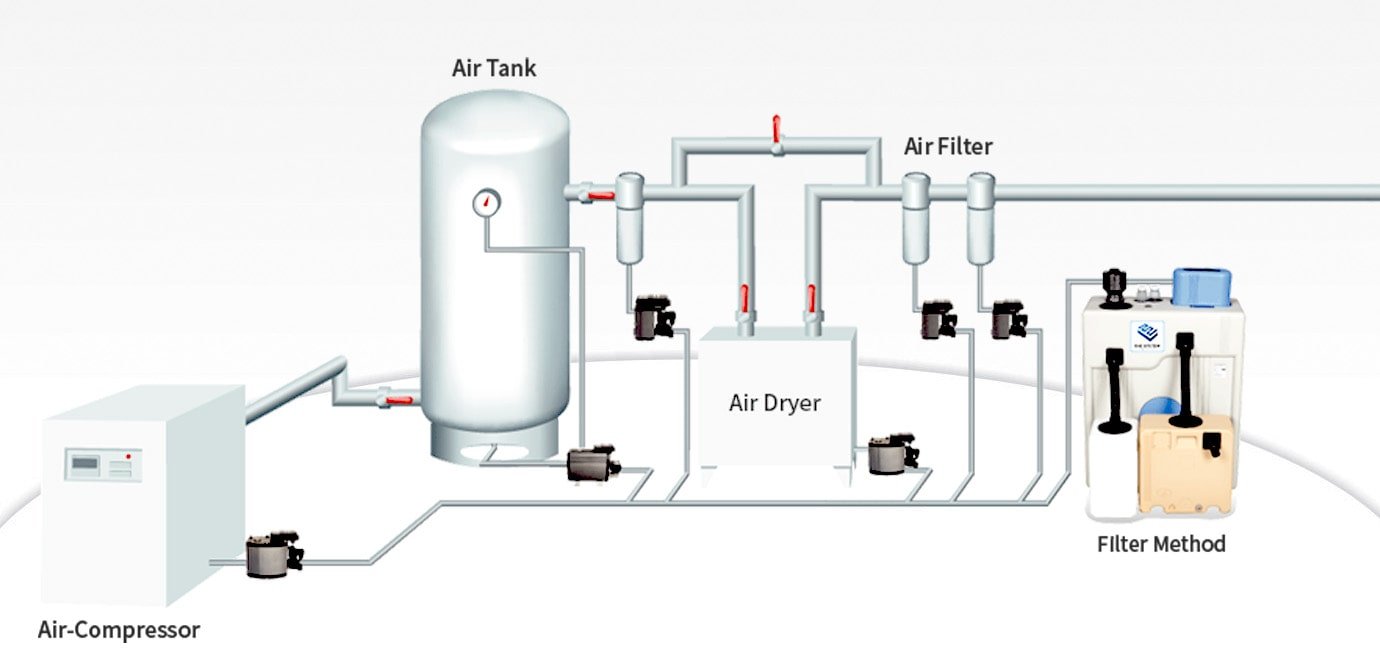

Analysis of zero air loss drain valve usage and cost of air loss

1. Analysis of Drain Valve usage

| Types of Drain Valve | Analysis |

|---|---|

| Time Control Solenoid Type | A large amount of air is lost because condensate is discharged via time setting regardless of the amount.. |

| Float Type | The trap has low reliability and experiences frequent clogging due to the small nozzle diameter (0.7∅). |

| Manual Valve Open | Compressed air, produced by high-cost power, is discharged into the air in order to discharge condensate. |

2. Cost of air loss per Drain Valve

| Drain Valve types | Air loss calculation |

|---|---|

| Time Control Solenoid Type | KRW 562,000/1 point x 9 EA = KRW 5,058,000 / year |

| Manual Valve Open | KRW 1,686,000/ 1 point x 9EA = KRW 15,174,000 / year |

| Level sensor type(Drain Master) | Zero |